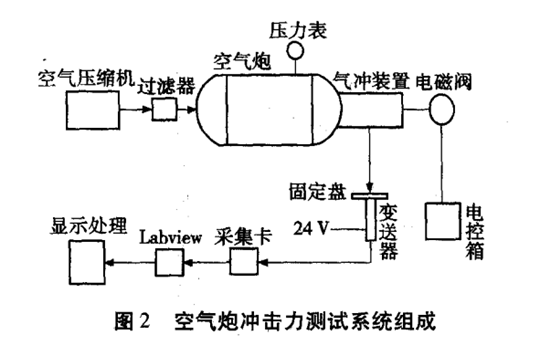

The test system is mainly used to test transient impact pressure of air cannon spray explosion. This system is mainly composed of air cannons, ZBM-0.067/8 air compressor, filter, two-position two-way solenoid valve, NIPCI-6014 data acquisition Card, data acquisition software, CYG1145 dynamic high-frequency pressure transmitter and l PC machine. The high-frequency dynamic pressure transmitter is a pressure measuring element, and data collected by pressure transmitter is converted into A/D through the data acquisition card, connected with the computer by PCI bus, and pressure data collection process is completed. The software of test system development is based on LabVIEW, and main functions of this system software are real-time waveform display and analysis and storage of test results. The composition of industrial air cannon impact test system is shown in Figure 2.

Working process of the test system is: compressed air from air compressor first passes through air filter to filter out impurities and part of water, and filtered compressed air enters air cannons, and air cannon is ready to fire. After switch on electric control box is turned on, solenoid valve acts, air blast device of air cannon loses balance and opens, compressed gas in air cannon expands rapidly in a short period of time, and acceleration of air flow through the muzzle of air cannon reaches and exceeds The sound velocity and high-speed air flow impact on stress surface of sensor, and high-frequency pressure transmitter outputs different voltage signals according to the impact force received. The voltage signal is received by the data acquisition card and input to computer after AD conversion. The data in computer acquisition software program displays the waveform and data after processing the acquired data and saves them.