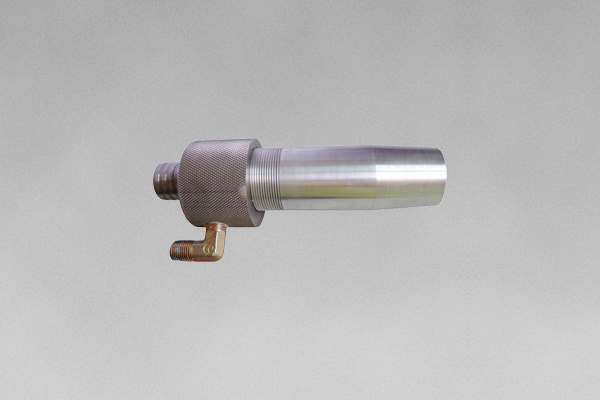

Light, easy to disassemble.

Beautiful and durable

Sandblasting nozzle is wear resistant.

Performance and lifespan of the special sandblasting head for rust removal has reached the world's advanced level.

This water sandblasting nozzle is light, easy to disassemble, beautiful and durable, and the sandblasting nozzle is wear resistant. In mixing chamber, negative pressure of water is used to spray water-sand mixture through sandblasting nozzle at high pressure to generate a strong impact force, and high-pressure equipment is used to drive abrasive to co-constructed surface to perform microscopic cutting or impact on the surface of the workpiece. To achieve the cleaning effect, water sandblasting nozzles can be widely used in surface treatment such as paint removal, rust removal, concrete cutting, roughening, etc., ships, aircraft, metallurgy, mining, railways, bridges, chemicals... Application of hydraulic sand cleaner (high pressure cleaning equipment) replaces original Some lag behind the sand cleaning process, sandblasting cleaning equipment is easy to operate and has high removal efficiency. Performance and lifespan of the special sandblasting head for rust removal has reached the world's advanced level.